What Is Icc Profile In Photoshop

Terminal Updated: 22/eleven/2020

about icc colour profiles

ICC profiles explained

Here you'll find information on what ICC profiles are, descriptions of the basic types, an explanation of why they are of import to yous and info about how they are made and used.

Simply put - a skilful ICC profile provides an accurate description of the characteristics of a digital device or working colour space.

sections below

why are accurate ICC profiles needed

RGB working spaces

input profiles, for cameras and scanners

the monitor display system profile

output profiles, printing

softproofing

profiling the printing press

how profiles work - some in depth explanation

making a printer contour, more item

gratis profiles

does anybody demand adept ICC profiles

why are accurate ICC profiles needed?

In the chain of capture or scan > view > edit > proof > reproduce, at that place may be restrictions due to equipment capability, i.east. limitations to the range of colour and tone which whatever specific digital device can handle capture, brandish or reproduce, this range is known every bit a device's "effective gamut". Authentic description of device gamut is one very of import office of an ICC contour.

No affair how advisedly devices such as brandish screens and printers are manufactured, there are inevitable minor variations, even from the aforementioned production line. Added to this is the problem of mixing devices from different manufacturers or product lines. So each device might interpret the numbers in an image file differently and if we don't accept control each device is likely to produce differing colour and tone from that intended.

Ideal working practise requires an automatic style of describing the capabilities of each digital device and a mechanism to recoup for the performance of each. With the right settings, the colour management system fulfills this demand by using each device'south ICC profile and its ability to unequivocally* and accurately describe device capabilities. The colour direction system tin can at present properly translate digital data between devices using those ICC profiles in society to maintain appearance, inside limits of device capability, of course.

Fortunately there are many excellent measuring tools and software which allow us to brand accurate ICC profiles for our diverse devices.

*Unequivocal / Unequivocally are vital terms in color management, basically they mean: leaving no doubtfulness, clear, unambiguous.

the UGRA FOGRA "Media Wedge", used to check profile accuracy in proofing.

The Media Wedge, above, allows comparison of printed colour on a proof directly with a press reference, so can guarantee a friction match from proof to press.

RGB working spaces are device contained

An RGB working space is a specific type of color space, defined past its ICC profile, it is effectively the hub of many contour based conversions. A basic bit of advice, no NOT set your Adobe Photoshop RGB workingspace to the display profile. Please read on - for info on the need for and reason for working colour spaces.

Back in the late 1990'south, with Photoshop 5, Adobe introduced an invaluable concept to its users, the RGB working infinite. These "device independent working spaces" are designed to be used for editing and storage or archiving of images. Dissimilar printer, scanner, camera or display screen profiles, working spaces are not used to describe specific devices.

converting image data between color spaces, more detail

Converting image information from an input color space (due east.grand. "camera.icc" or "scanner.icc") to a working space ("workingspace.icc") will re-marshal the often not-linear (wonky*) RGB numbers, so that the editing process is more predictable. Advent is normally unchanged by this conversion, equally long every bit the working infinite has sufficient volume to enclose the incoming data. Working infinite pick is a very important part of a workflow, which should ideally exist designed to preserve all of an image's data.

*Wonky? Whereas a device colour space is often not-linear, an RGB working space is both grayness-balanced and perceptually uniform. These qualities mean that when editing different regions of color and of tone, i.e. saturated or pastel, nighttime or light, results volition exist consistent and predictable. What's more, a set of matching RGB numbers will always equal neutral gray, right from RGB 0,0,0 to RGB 255, 255, 255. This important feature allows for like shooting fish in a barrel i-click neutralisation of global colour casts in many images. Linearity of behaviour in editing is vital if the procedure is to be predictable, this is inappreciably ever the instance if working inside a device based colour space.http://www.colourmanagement.net/downloads_listing

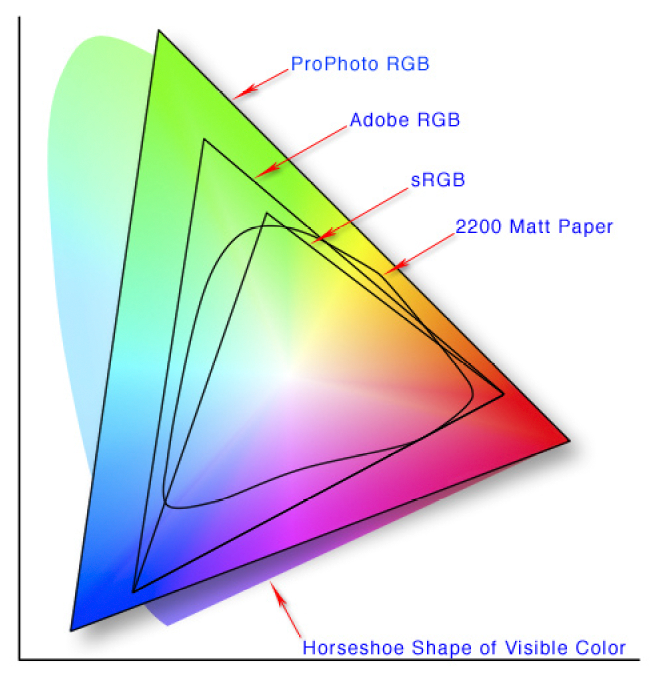

Each working space is designed to encompass a specific range of colour values (illustrated right in a simplified two dimensional projection), the designed range or "gamut" is oftentimes relative to a particular group of prototype sources or image destinations. Nevertheless, do call back that working spaces take no direct relation to whatever specific device, hence the term "device independent working space". It is worth noting, too, that bigger isn't ever better when information technology comes to working infinite pick, in fact choosing too big a working infinite for your workflow can create issues. It's important, therefore, that workflow is tested and a working infinite is advisedly selected.

In summary, the RGB working space functions as a container for tonal and colour data independently of any specific device. A well chosen working space volition be large enough to contain all the image information from a item source, be information technology camera or scanner.

Working Spaces, use in image storage & archiving

When a file is being edited in Photoshop it will ideally be kept in a properly suitable RGB working infinite.

As well as anticipated editing, this practice also offers future-proof repurposeability. Archiving all the original image tonal and colour information within a suitably sized working infinite, rather than, say, data converted to a printer colour space, allows scope for repurposing to have advantage of future improvements in imaging; perhaps a novel printing procedure of the future will let far more of the original colour to be reproduced than with today's applied science.

For instance, imagine finishing the editing of a beautiful epitome, at this time perhaps simply intended for utilise in newsprint, apart from the inevitable colour and tonal edits to adapt the restricted colour range available, at some stage the image data will need to be converted into the newspaper's color infinite (e.1000. news.icc) so that it will suit the press process. Perhaps the operator inadvisedly saved this converted version over the original prototype - thus, only retaining the news.icc version, a pretty unsaturated CMYK file.

One-time in the futurity, this same image may unexpectedly be wanted for a job where original gamut could exist well utilised. What if that newspaper image really turned out to exist of a popular subject, maybe now, you'd like a large inkjet print for an exhibition. The inkjet printer would probable be able to do a groovy job of reproducing your lovely original scene, since the procedure has a pretty good colour gamut. However, considering you now only accept the news.icc file, all that tin be printed is a large version of the de-saturated picture. Y'all tin, of grade, add together saturation, but yous can't bring back the subtlety, detail and beauty of the original. If a version of the image stored in a decent sized working space had been archived, you'd be in a much better position. Information technology would accept been repurposeable. That's why working spaces are important as storage color spaces.

Also note that ANY CMYK file will likely have had its gamut reduced from the original RGB, then, where possible, always archive an image as RGB, within an RGB working space. Not merely the CMYK conversion. Preferably salve as an uncompressed format similar .tiff or .psd, certainly Not as a JPEG, since the JPEG tin't even exist resized without further damaging compression.

Example Working Spaces

AdobeRGB(1998).icc, intended to encompass most of the colours found in a photographic image on film, simply a little restricted for that purpose.

sRGB Color Space Contour.icc, designed to contain all the colours we can expect to see on an boilerplate PC monitor.

Chrome Infinite 100, J. Holmes.icc, meticulously designed to enclose well-nigh all the colours an Ektachrome motion-picture show tin record.

Please scroll down the downloads page to find "workflow tools for sophisticated photographers and retouchers where you can learn more than about Joseph Holmes' working spaces.

The working color infinite sits at the centre of colour management. Each relationship with an external device, exist it a scanner, monitor screen or printer, is provided for via an ICC contour which describes each device and thus allows translation between a working infinite and the various devices.

input profiles, for cameras and scanners

Input profiles are a type of device colour space. Digital cameras and scanners are profiled in a dissimilar way to printers, one similarity, though, is that much of the procedure depends on suitable software settings and repeatability. In order to make an input contour, the camera or scanner is set to a repeatable state and a physical profiling target is captured equally an epitome which is and then analysed.

For cameras, a suitable target would exist the basICColor DCAM or ColorChecker SG (pictured).

For scanners a high quality target would be a HutchColor Target, "HCT", or, for less disquisitional processes, an IT8 mode target, either transparency or cogitating.

Commencement the target is carefully captured using expert repeatable software settings.

Next, the captured target paradigm values, expressed as RGB, are evaluated inside the profiling software and a transformation table is created, which provides for translation between RGB device values and the known 50*a*b* values sourced from the target reference file. This ways that now whatever RGB value in a file from the relevant input device can be cross referenced against unambiguous vales related to human vision.

This ICC input profile can now be used when opening any capture or scan made using the "profiled" device as long as the device remains consistent. The ICC profile will effectively filter out consequent undesirable device characteristics like a caste or tonal anomaly.

In practice, the ICC profile is assigned to each capture or scan and this action provides an imaging awarding similar Photoshop with the information needed to translate the file's numbers, including the ability to produce accurate advent on screen. Accurate screen brandish is achieved in a transformation or "conversion" using the input profile, the display contour and perhaps also a working colour infinite profile.

An accurate ICC input contour can certainly salve some work by minimising the repetitive editing tasks often necessary to correct consistent digital camera or scanner variations.

A proficient input ICC profile is also used by color direction savvy RAW processing or scanning software to provide an accurately colourmanaged screen brandish during the process of capture. This provides the advantage of continuity of prototype advent from the capture application to, for instance, Photoshop.

If we are to utilize the sometimes fantabulous colour and tonal editing tools available in RAW processing or scanner software, it is imperative to use good ICC profiles - so that, ideally, whatever image optimisation nosotros've done using input software will still be valid once viewing the epitome in Photoshop.

Without adept colour direction, appearance is unlikely to be continuous between applications, i.eastward. although optimised within scan or capture software, the image might and then seem to change significantly once saved and and then opened in Photoshop. In this case it tin can be a matter of starting over again with adjustment, quite a waste of endeavor and time.

more about input profiling and my profiling service hither

the monitor display organisation profile

Display profiles are a type of device color space. Monitor display profiles are part of what is maybe the most important colour management of all, since the display screen is our only window on digital content. Brandish system profiles are fabricated in a process which uses an authentic screen sensor like basICColor'due south discus device pictured here - and practiced software like basICColor Brandish (right) to assess the display system capabilities and build the ICC profile which describes them.

Display profiles are a type of device color space. Monitor display profiles are part of what is maybe the most important colour management of all, since the display screen is our only window on digital content. Brandish system profiles are fabricated in a process which uses an authentic screen sensor like basICColor'due south discus device pictured here - and practiced software like basICColor Brandish (right) to assess the display system capabilities and build the ICC profile which describes them.

In a standard brandish system the first step in the procedure calibrates the system, loading a Wait Up Table ("LUT") to the systems video carte - footstep two and then measures calibrated appearance to produce an ICC profile.

Hardware calibrated displays are similar in practice, simply, in the background, the calibration LUT is really loaded straight to the screen's internal circuits which operate at a higher fleck depth to optimise the transformation of paradigm data during display.

(only the calibration software can load that LUT, beware switching profiles in any other way).

On completion of the procedure, the resulting ICC display contour is built, containing both the scale instructions for the figurer's video card (where relevant) and the device characterisation table used past a colour-management savvy application like Photoshop to correctly brandish image files.

Good calibration and profiling software will provide a broad range of scale target settings which are used in order to tune and optimise screen advent, these options are vital since e.k. optimal targeted luminance and white point are prepare relative to work room lighting weather condition.

Higher up right: basICColor Display Software verification screen.

output profiles, printing

Output profiles are a type of device colour infinite. Permit's starting time with an inkjet printer; this is profiled by first choosing suitable options from among all the available settings in the printer's RGB commuter or CMYK RIP software. Options such as resolution and media type can all affect output, and so must be optimal.

Output profiles are a type of device colour infinite. Permit's starting time with an inkjet printer; this is profiled by first choosing suitable options from among all the available settings in the printer's RGB commuter or CMYK RIP software. Options such as resolution and media type can all affect output, and so must be optimal.

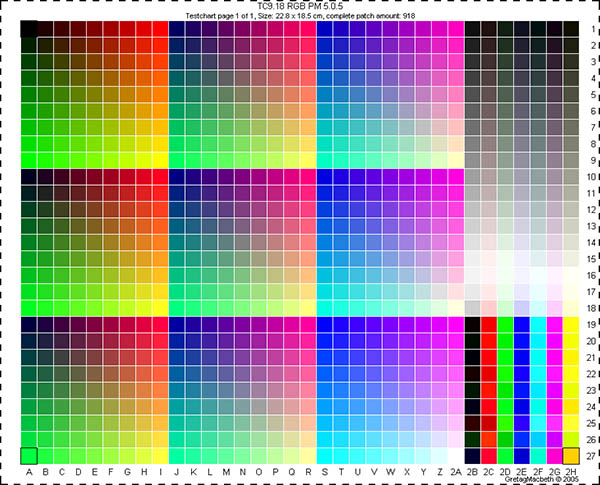

Next, exam prints of a relevant set of colour patches are fabricated, using the chosen software settings and using the correct paper and ink.

Later drying, authentic measurements of the test prints are made using a loftier quality spectrophotometer device.

Next, these measurements are analysed within the profiling software and, in a process of assessing both the measured patch values and the target reference data, the software can produce an accurate device characterisation - an ICC output profile.

Now, Adobe Photoshop, and other colour management capable programs, can use this ICC contour to adapt image data, equally information technology is sent to the printer. This means that we tin expect an accurate reproduction of the original image file, within the limits of gamut of the printer and paper called.

An ICC printer profile is specific to one certain printer, one type of paper, one inkset and, fifty-fifty, to one print resolution and media setting. If you buy a different make of ink or type of newspaper, or alter software settings, then the printer volition likely behave differently, this inevitably means that the contour nosotros made will no longer describe the printed behaviour. So, now, the procedure of printing using the ICC profile fails to give an accurate printout. A new contour would be needed in order to assess the printer's new behaviour.

The demand for consistency is often called "procedure control".

Because of the importance of consistency, it is non a expert thought to use low cost "compatible" ink cartridges when profiling, because the vital continuity of performance using those inks is very unlikely - due to poor quality command, they often differ, 1 to the next.

Also as on-site profiling, we likewise offer remote inkjet profiling, hither.

softproofing, proofing on a monitor display system

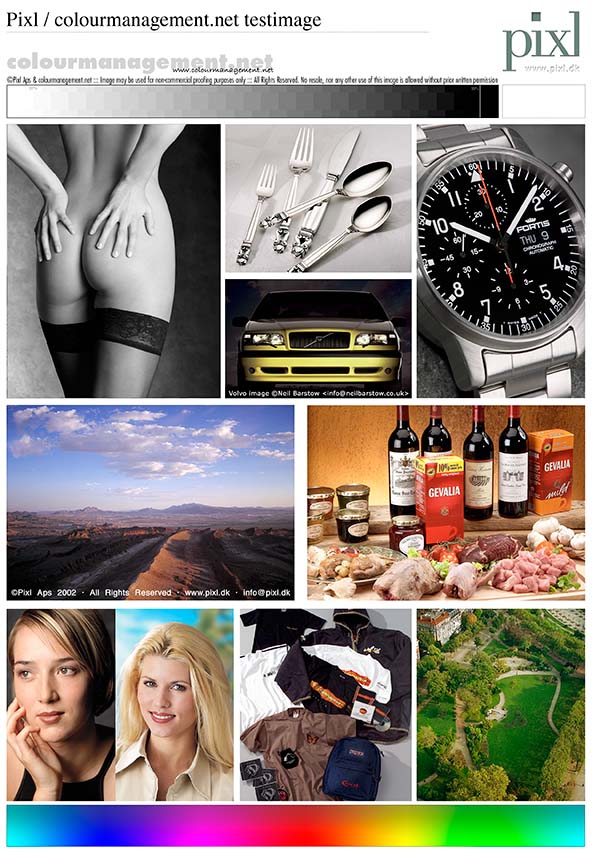

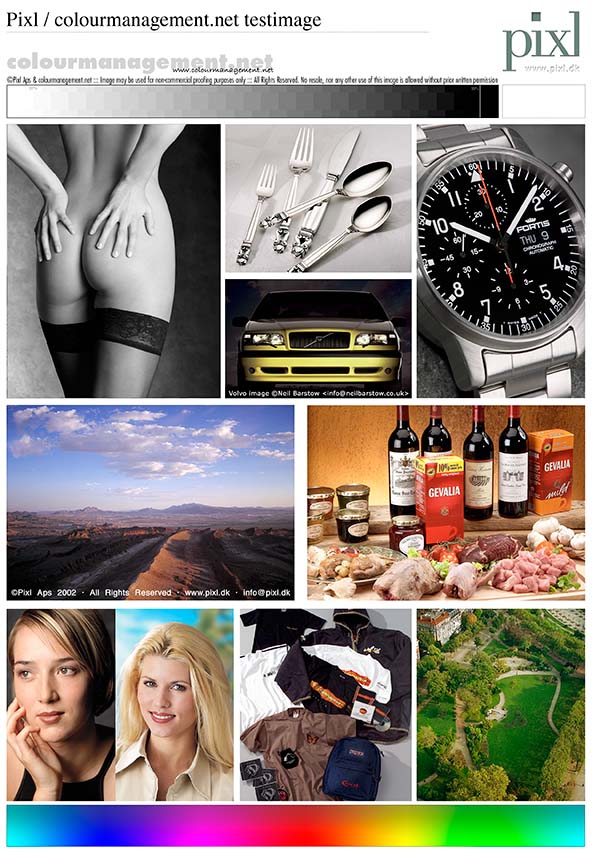

Good printer profiles tin can too be used inside colour management savvy applications like Adobe Photoshop for on-screen softproofing in social club to predict printed output. Softproofing ways that a screen preview, simulating the output of a printer, can be viewed during image optimisation.

Of course, accuracy in softproofing relies entirely on having a decent quality, well calibrated and profiled, display arrangement as well as a skillful authentic output (printer) contour.

press profiling

In a very like procedure to that outlined to a higher place for inkjet printers, (i.e. optimise, print, measure, run in a constant state) a printing press can be profiled too. However, it is important to understand that profiling a press properly is quite a big task. It'due south very of import to analyse a press for profiling in a well optimised state, that can take a lot of fourth dimension.

In a very like procedure to that outlined to a higher place for inkjet printers, (i.e. optimise, print, measure, run in a constant state) a printing press can be profiled too. However, it is important to understand that profiling a press properly is quite a big task. It'due south very of import to analyse a press for profiling in a well optimised state, that can take a lot of fourth dimension.

Printing press ICC profiles are vital as they are used for conversion (separation) of RGB files to CMYK, too for both printed proofing and softproofing. There is no "just use CMYK" any longer, each printing type and paper type has it's own ink recipes and those are respected in the freely available standards based profiles.

So, in that location is a more practical way to work than past than profiling each printing individually. Almost all presses tin exist run in accordance with specific ISO standards, which means that RGB to CMYK separations no longer need to be made for each specific press automobile. What is on the plates is easier to piece of work with which makes for faster more than efficient utilize of the machine.

Standards based ICC profiles upshot from standard press runs measured by technical experts - "standard" printing ICC profiles are available freely. These ICC profiles are available from the European Colour Initiative.

More information about pre-press and standards based working hither.

Checking ICC profile accuracy, a high quality well controlled visual test is the ultimate way I feel more on testing display and print profiles here.

how profiles work - some in depth explanation

At that place'due south some science in here in the tech box, and information technology's not necessary to fully empathize this section, but many users observe it helpful to take at least a basic knowledge of the workings of ICC profiles, so they end to go quite so mysterious.

ICC profiles are vital because the RGB and CMYK values in whatsoever digital file have no unequivocal* values unless associated with an ICC profile. Once a profile is associated (or "assigned" in Photoshop terminology), then the relationship between the file's numbers and human being vision is established. (i.due east. RGB or CMYK can now exist converted using either of the scientifically defined unequivocal human vision based colour spaces XYZ or L*a*b.)

*Unequivocal means: leaving no doubtfulness, clear, unambiguous, a useful term in color management.

An instance: the RGB values R=10, G=100, B=10 take no meaning by themselves other than the color is greenish. That's because the actual colours of the constituents, Ruddy Green and Blue are not defined. By associating a colour space definition, (i.e. by assigning and embedding an ICC profile) the same RGB values are translated into XYZ or L*a*b giving the values an exact meaning related to homo vision. The information tin can at present be a passed off to a brandish screen or to a printer in a procedure that uses those exact color definitions - terminating in a conversion to optimise the information for the receiving device.

Having a set of RGB or CMYK values associated with a defined colour space (as in "with an embedded ICC contour") allows for the verbal reproduction of the color.

near L*a*b* and XYZ color spaces

You'll hear mention of these color spaces and their apply as way of defining colour, when you're getting into agreement ICC profiles. And so, what are they? Both L*a*b* and CIE XYZ colour spaces are designed to cover human vision. These colour spaces ascertain colour using a full scale, based upon how humans see color, so that a detail set of values always means the same colour. As you learned above, RGB and CMYK don't work like that.

CIE Fifty*a*b* (normally named simply Fifty*a*b*) colour infinite is based on the CIE 1931 XYZ color infinite, formulated to contain the whole range of colours and tones visible to the man center and referenced past numbers that provide unequivocal colour meaning. The CIE XYZ colour space was derived from a series of experiments done in the tardily 1920s, experimental results were combined into a specification from which the CIE XYZ color space was derived.

In summary, XYZ and L*a*b* numbers are unequivocal. Unlike numbers in the RGB or CMYK colour models, Fifty*a*b* and XYZ numbers have an actual meaning.

F.Y.I.

L*a*b*: Fifty*= lightness centrality, a = Green to magenta axis, b = Blue to Yellowish axis.

XYZ: Y is luminance. Z and X are related to human being cone response curves.

At that place are lots of papers online for those who'd like to delve further but that's certainly non needed in a quest to improve empathise how ICC profiles work in practise. Just appreciate that XYZ and 50*a*b* ascertain colour properly, unequivocally.

ICC profiles

Any ICC profile contains one or more tables to allow calculation between "device colour space" ICC and XYZ or L*a*b colour space, or the changed.

Any ICC profile contains one or more tables to allow calculation between "device colour space" ICC and XYZ or L*a*b colour space, or the changed.

Even a working colour infinite like AdobeRGB(1998).icc (3D pic. right) is treated as a "device colour infinite" in this scenario. Some ICC profiles do contain quite a few tables to allow for conversion using different rendering intents, but, basically, all those tables do is to provide for variants on the above calculations.

L*a*b* or XYZ are used in ICC profiles as the Contour Conversion Space or P.C.Due south. - because they are unequivocal, each numerical value in either XYZ or L*a*b defines a unmarried colour relative to human vision.

Basically, the following describes the manner the profiles are used in an RGB or CMYK print conversion

A: "document" (perhaps an paradigm) RGB or CMYK converts to XYZ or L*a*b

- so -

B: XYZ or Fifty*a*b converts to printer RGB or CMYK.

Liken this to translating a word from French to German without admission to a French to German lexicon.

If you had a French to English dictionary and an English to German language one you lot could practise it in two steps:

A: Translate from French to English

- and -

B: Interpret from English to German.

In this example English is acting as the "conversion space", the P.C.S.

When a conversion between two colour spaces takes identify we are normally offered a choice of rendering Intent. For output conversions all the intents, Perceptual, Relative Colorimetric, Absolute Colorimetric and Saturation are all available within the process and will affect the issue. Yet, when converting from an input color infinite to working space, although Photoshop offers the options above, all that's actually available is a form of Colorimetric rendering. There are some important implications to this because image information tin can be clipped during the conversion process which may happen unnoticed in the background. Issues arise especially if the working space is not large enough to contain all the prototype data which happens all to often. Disappointment with paradigm quality, especially in detail in dark, low-cal or saturated areas may result and, although this may be idea an inevitable part of the process, at that place are sophisticated ways of controlling it. Taking control of this, by careful working space choice and properly managing the process, is something I provide grooming in.

making a printer profile, in detail

In an effort to make a description of the ICC print profiling procedure easy to encompass, many writers, myself included, have alluded to a process of comparison between printed results and the actual desired appearance of the patch file. That's not entirely wrong in spirit, simply, technically, calculating an ICC profile is NOT a process of comparison of printed (output) to patch values. This is because the patches actually have no "platonic" advent (i.e. no L*a*b* values - please read on to understand that better). The ICC contour does have an power to arrange color information (perhaps in an image) before press and, thus, the consequence is printed material that compares well to desired or "correct" appearance. Then, adept comparison is the finish result, but comparison's non included in the actual procedure of making the ICC profile.

In practice, L*a*b* measurements of the printed patches are analysed inside the profiling software and, in a process of assessing how the measured patches (measured in 50*a*b*) relate to the target reference data (expressed as RGB or CMYK), the profiling software tin can produce an accurate device characterisation - a table for calculation betwixt L*a*b* and RGB or CMYK, which is used in the ICC output profile.

Y'all read earlier that RGB and CMYK values are cryptic, considering the primaries are non defined, well, hither in the printer profile, the ambiguous file values of the target are made unequivocal by the table calculating between printed output and target values.

The ICC profiling procedure involves a few steps, which are worth explaining

1: set up-up printer and impress a file with RGB or CMYK patches

It's vitally important at this stage that either the printer command software (i.e. driver or RIP) settings or press adjustments (CTP tone curves, ink weights etc.) are chosen properly; often this ideal motorcar land is reached as a result of a process of step-past-step testing of various options. This method optimises the process. Thereafter, those same settings must be used whenever the profile is to exist used. Consistency is king, car behaviour must exist changeless.

It's vitally important at this stage that either the printer command software (i.e. driver or RIP) settings or press adjustments (CTP tone curves, ink weights etc.) are chosen properly; often this ideal motorcar land is reached as a result of a process of step-past-step testing of various options. This method optimises the process. Thereafter, those same settings must be used whenever the profile is to exist used. Consistency is king, car behaviour must exist changeless.

And so, what are we press in this patch file? The RGB or CMYK patch information in the image file is allowed no embedded ICC profile, so it has no associated Fifty*a*b* or XYZ "visual" values and nothing to inform a conversion to L*a*b* or XYZ, thus, there is no mode that its values tin actually exist related to a visual colour meaning. The file data has no unequivocal appearance, the numbers are ambiguous.

How can we see patches on screen and so? On screen brandish of patch files is, as default, made using a "guess"** as to document colour infinite.

We must not assign an ICC profile to patches in practice, considering it could invalidate the printing process. We need raw CMYK or RGB patch data printed.

Simply, if an ICC profile were assigned** to the file with the patches, and then the colour direction process would provide L*a*b* or XYZ values for each patch and, this information, passed through the monitor profile, can provide what is shown on screen with a visual appearance. So we have now given those patches "unequivocal" values - but this is only ane possible appearance, i estimation for the values of those RGB or CMYK patches, because if a different ICC profile was assigned to the patch file, then the visual appearance would modify, (this happens because the calculated L*a*b* or XYZ values would alter).

**In Photoshop and similar applications, when an epitome without an ICC profile is displayed, the 50*a*b* or XYZ data normally provided by a profile is missing. And then, it'due south not possible to send the data through the screen profile to the screen - therefore, to let display, Photoshop assumes (i.east. temporarily assigns, for viewing just) the default working colour space profile – just so the file can be shown on screen. This doesn't touch the printing process, but it does explain why the file appears to have a set appearance on screen.

2: measure the printed target

The printed patch set up is measured using an accurate spectrophotometer.

As you read above, after printing and reading the target no comparison to anticipated results is actually fabricated, because in that location is no anticipated effect for the printed patches.

Then, what does actually happen?

three: summate the profile

Colorimetric values in XYZ or 50*a*b* event from the measurement of the printed target. Reference information for the patch set up containing the original RGB or CMYK values for each patch is used, in conjunction with those measured values, to calculate and build the "device values to XYZ or L*a*b*" table which is part of the ICC contour, this is called the A2B transformation table. This tabular array but describes the printer to software, then that the organization "knows": "What happens if I send particular RGB or CMYK numbers to printer - what actual colour (what visual advent) will result".

This table A2B is not actually the part of the output contour used when converting a file to print it, it's an "inversion" of that table - into an XYZ or Fifty*a*b* to device transformation table,called the B2A, that provides the information needed for this important transformation. What the organisation tin larn from this table is "I have read the profile of a pixel in the prototype, so now I take an XYZ or L*a*b* value to print; what RGB or CMYK numbers do I need to ship to the printer to get that advent?"

Using the printer contour, printing

Using the printer contour, printing

When selected in an imaging awarding like Photoshop, the printer'south ICC contour provides a prediction, which is used, forth with the certificate contour, to piece of work out how to alter each of the certificate file's pixel values to get a print that looks similar it should. That is, it should closely lucifer the source image shown on a calibrated and profiled display screen, or another impress from a profiled workflow.

It works like this, document RGB or CMYK is converted to XYZ and and so XYZ is converted to device RGB or CMYK.

As well as on-site profiling, I as well offering remote inkjet profiling, here.

Using the printer profile, softproofing

Good printer profiles can be used in on-screen softproofing in order to predict printed output on a well set upwardly monitor screen. This useful output preview process is available in Photoshop and some other imaging applications; softproofing provides a screen preview, simulating the output of a printer, which tin can exist viewed during image optimization. Of form, accuracy in softproofing relies on having a decent quality, well calibrated and profiled, Brandish System and a good accurate output (printer) profile. Without going too deep, the process involves the original file'southward values passing "through" the printer profile en-route to the display profile.

document RGB to XYZ or L*a*b*-and- XYZ or Fifty*a*b* is converted to printer RGB (or CMYK)

printer RGB (or CMYK) to XYZ or L*a*b*-and- XYZ or L*a*b* is converted to display RGB

using a camera or scanner ("input") contour

The ICC input profile is used to compensate for consistent issues in the capture or scanning process. The relevant ICC contour is assigned to the paradigm when opening any original capture or browse. In many software applications, the profile can exist assigned and embedded automatically. Assigning the ICC profile to an incoming image provides for accurate appearance on screen through a transformation using the input profile and display contour - and, often, besides the chosen working colour space profile.

The ICC input profile is used to compensate for consistent issues in the capture or scanning process. The relevant ICC contour is assigned to the paradigm when opening any original capture or browse. In many software applications, the profile can exist assigned and embedded automatically. Assigning the ICC profile to an incoming image provides for accurate appearance on screen through a transformation using the input profile and display contour - and, often, besides the chosen working colour space profile.

In initial display on screen, one time the device ICC profile is assigned, each pixel in the RGB image file is

A: transformed to XYZ or L*a*b* - and then -

B: XYZ or L*a*b* is transformed to monitor space RGB ICC.

In most cases device RGB is converted to a working space offset, then

A: device RGB to XYZ or L*a*b* - and -

B: XYZ or L*a*b* is converted to working infinite RGB ICC.

- then -

C: working space RGB ICC is converted to XYZ or L*a*b*- and -

D: XYZ or 50*a*b* is converted to monitor space RGB ICC (or even printer colour infinite ICC if press at this stage).

Much of this is dealt with automatically in a well set-up system.

profiles for free?

Unfortunately, still well intentioned they may exist, ICC profiles supplied with products or found around the internet which might claim to accurately represent a detail device can often be quite poor. Since each individual device may differ, these "canned" or generic profiles are sometimes only useful as a starting point. In some instances the provider fifty-fifty fails to provide instructions on device settings for use with their profile.

Making a profile from i printer and attempting to use that same profile on a dissimilar printer, even if it'south the identical printer model using identical paper and inks, is unlikely to provide identical or accurate results.

Success with colour management relies on proficient device characterisation, provided by ICC profiles and on consistency in devices and working methods.

does everyone need skilful ICC profiles?

In even the most basic workflow, if the aim is to view images with truthful colour, nosotros need a monitor profile and a certificate (image) contour in order to accurately view that image. So, yes, anyone viewing images on a estimator monitor screen needs decent ICC profiles.

Checking ICC contour accuracy, a loftier quality well controlled visual test is the ultimate way I feel more on testing display and print profiles here.

Exercise y'all need assistance with the above? Y'all can make it touch for gratuitous chat, just follow the link to my free consulting page.

dorsum to the meridian of the page

Source: https://www.colourmanagement.net/advice/about-icc-colour-profiles

Posted by: rodgersimas1998.blogspot.com

0 Response to "What Is Icc Profile In Photoshop"

Post a Comment